Valve Strainer is a key safety device in fluid transport systems. They trap impurities and protect components such as valves, pumps, and flow meters from wear, clogs, and damage. The Strainer’s mesh size is the main factor in its performance, affecting efficiency, pressure drop, and equipment lifespan.

This article explains the main points of filter mesh size, including definitions, how to choose the right size, factors that affect selection, industry standards, and real-world examples. It serves as a practical guide to designing, operating, maintaining, and selecting filters for industrial fluid systems.

The Core Definition and Measurement Logic of the Mesh Number of Valve Strainer

1. The Essence of Mesh: Not “Aperture”, but “Density.”

Many industry practitioners think mesh size means aperture, but this is incorrect. The correct definition of mesh size is the number of mesh openings per inch (25.4mm). For example, a 20-mesh filter has 20 mesh openings spread across 1 inch.

A higher mesh size means more holes per area, smaller hole diameters, and greater filtration accuracy.

Mesh size and pore size are not directly linked, as wire diameter affects pore size. With the same mesh size, thicker wire makes smaller pores, while thinner wire creates larger pores.

For example, a 100-mesh 304 stainless steel Strainer has a pore size of about 150 μm with a 0.1mm wire, or 130 μm with a 0.12mm wire. So, don’t just look at mesh size—also consider the material, wire diameter, and other factors to judge how well the Strainer works.

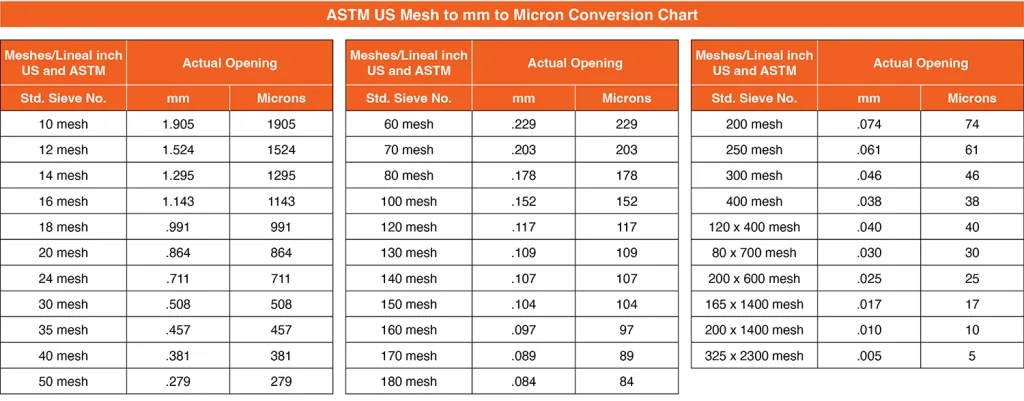

2. Common mesh size-to-aperture correspondence (industry standard)

For practical use, here is the mesh size and aperture relationship for industrial valve Strainer. This is based on GB/T 6003.1-2012. Assume 304 stainless steel and 0.1mm wire diameter by default.

-10 mesh: with an aperture of approximately 2000μm (2mm), designed to intercept large particulate matter such as welding residues and stones in pipelines;

-20 mesh: aperture about 850μm(0.85mm), often used in raw water pretreatment, sewage coarse filtration, and other scenarios;

-40 mesh: aperture about 425μm(0.425mm), suitable for general industrial fluid filtration, such as cooling water, lubricating oil preliminary filtration;

-60 mesh: aperture about 250μm(0.25mm), can intercept small particle impurities, protect the valve core of ordinary valve;

-100 mesh: aperture about 150μm(0.15mm), suitable for precision valves, flowmeter pre-filtering;

-200 mesh: aperture about 75μm(0.075mm), used for high-pressure hydraulic systems, precision instrument matching filtration;

-300 mesh and above: with pore size ≤45μm, ideal for ultra-precision filtration applications such as ultrapure water in electronics and high-purity medium filtration in chemical industries

The core logic of mesh size selection: Balance of filtration precision and system adaptability

Choosing the right Strainer mesh size is about finding balance. It should remove impurities well, but not cause too much pressure drop or clogging. The main idea is to match the Strainer to your system’s needs. Four main factors help guide this choice:

1. The ‘tolerance threshold’ of clearly defined protected objects

The primary criterion for equipment selection is the impurity tolerance of the protected device, defined as the maximum permissible particle size of impurities. Different devices exhibit significantly varying sensitivity to impurities:

Gate valves and globe valves: Their valve core sealing surfaces are designed for wear resistance, capable of withstanding 100-200μm particulate matter, with mesh sizes available from 60 to 100.

Ball valves and butterfly valves: Their valve cores and seats have high sealing precision, but impurities may cause wear and leakage on the sealing surfaces. It is recommended to use Strainer with a precision of ≤ 100 μm, corresponding to 100-150 mesh.

Control valves and pressure-reducing valves: Their internal throttling components have minimal clearance and are highly sensitive to impurities, requiring filtration precision ≤50μm (equivalent to 200-300 mesh).

Pumps and flow meters: Components like impellers and sensors are prone to wear from abrasive particles. We recommend using mesh sizes ≥80, with specific adjustments based on the manufacturer’s specifications.

For example, in a chemical plant using pneumatic control valves, the manufacturer requires that the medium particle size be ≤ 50 μm. In such cases, a 200-mesh or higher filter screen should be selected to ensure proper particle retention and prevent valve core jamming or seal failure.

2. Adaptation to medium characteristics: Select materials based on viscosity, impurity content, and corrosiveness.

The medium’s physical and chemical properties directly affect the selection of mesh size.Medium viscosity matters. High-viscosity media like heavy oil flow poorly. If the Strainer is too coarse, it may block flow and sharply increase pressure drop.

For instance, in heavy oil transportation systems, a mesh size of no more than 60 is recommended. However, for low-viscosity media such as clear water and light oil, higher mesh sizes may be selected based on specific requirements.If a medium has more impurities, Strainer clogging happens more often. For dirty media like wastewater or sand-laden water, use low-mesh, large-pore Strainer from 10-40 mesh, and add a backwashing system. For cleaner media that need high filtration, use a multi-stage system: start with low-mesh Strainer for coarse filtration, then add high-mesh Strainer for fine filtration.Corrosive substances like strong acids or alkalis can damage Strainer screens. Fine mesh screens with thin wires are more likely to break from corrosion, causing filtration failure. In these cases, use corrosion-resistant materials such as Hastelloy or PTFE, and choose a lower mesh size to ensure strength.

3. Consider system conditions when selecting pressure, flow rate, and operating frequency.

The system’s operating conditions are equally critical for mesh selection.System pressure is important. In high-pressure systems (pressure 10MPa or more), fine Strainer with thin wires can break easily. Use moderate mesh sizes (40-100 mesh) and thicker wires, and add support for strength.

-System flow rate: Higher flow rates require larger filter surface areas. If the mesh size is too coarse, the flow capacity per unit area decreases, requiring a larger Strainer volume to meet the flow requirements.

For example, in a DN50 pipeline system for clean water conveyance, if the flow rate is 50 m³/h, a 60-mesh filter with the same diameter as the pipeline can be used. However, if a 200-mesh Strainer is selected, the Strainer diameter must be increased to DN80 to prevent excessive pressure drop.

For the systems that are run continuously and can not be stopped for maintenance (e.g., cooling water system of a power plant), the Strainer with a low mesh size and strong anti-clogging ability (e.g., 20-40 mesh) should be selected to reduce the frequency of cleaning the filter;Avoid two extremes: mesh size that is too low or too high. If mesh size is too low, fine impurities get through, reaching sensitive equipment. This can cause valve wear, sealing leaks, impeller damage, or even equipment failure and shutdown.

Risk of excessive mesh size: When the Strainer screen has too small a mesh size, it is prone to clogging by impurities, leading to increased system pressure drop and higher energy consumption. Severe clogging may cause a temporary interruption of medium flow, affecting normal system operation. Moreover, high-mesh filters are weak and prone to damage under high pressure and high flow, ultimately losing their filtering function.

Other Key Factors Affecting the Selection of Mesh Count

1. The limitation of mesh size by Strainer material The Strainer material’s mechanical strength and corrosion resistance decide its maximum mesh size.

Metal Strainer: Available in stainless steel (304, 316L), carbon steel, and Hastelloy, these materials offer high mechanical strength and can be manufactured into high-mesh filters (up to 1000 mesh or more), making them suitable for most industrial applications. Notably, 316L stainless steel Strainer offer superior corrosion resistance, enabling use in acidic and alkaline environments, and provide a wider selection of mesh sizes.

Non-metallic Strainer media: such as polytetrafluoroethylene (PTFE) and nylon, which exhibit excellent corrosion resistance but have relatively low mechanical strength. Their maximum mesh size typically does not exceed 500, making them suitable for filtering low-pressure, low-viscosity, and highly corrosive media.

Sintered filter screen: Manufactured by sintering metal powders, it offers uniform filtration precision and high mechanical strength, with mesh sizes ranging from 50 to 500. This type of screen is suitable for filtering high-pressure, high-temperature, and high-viscosity media, though it is relatively expensive.

2. The compatibility of Strainer structure and mesh size

The Strainer’s structural design also affects the selection of mesh size.

Basket-type Strainer: Featuring a basket-shaped mesh with a large flow area, it can accommodate more impurities. Medium to high mesh sizes (40-200 mesh) are recommended, commonly used for main pipeline filtration.

Y-type Strainer: Compact design with minimal installation space, though its flow area is relatively small.

with excessively high mesh sizes (≥200 mesh) are prone to clogging. A mesh size of 100 or less is recommended, making it ideal for branch pipelines and low-flow systems.

Back washing Strainer: Features automatic cleaning without shutdown maintenance. Even with high-mesh (200-300) filters, they prevent frequent clogging and are ideal for continuous operation systems.

3. Industry norms and standard requirements

Certain industries have explicit standards or specifications for valve Strainer mesh size, and strict compliance is required during selection.

In the petrochemical industry, according to SH/T 3085, the Strainer mesh size for centrifugal pump inlet Strainer must be ≥40 mesh, while that for Strainer before control valves must be ≥100 mesh.

Power industry: The DL/T 5054 standard specifies that steam turbine cooling water Strainer must have a mesh size of at least 60, while hydraulic system Strainer require a minimum of 200 mesh.

Water treatment industry: GB 50268-2019 standard specifies that the mesh size of Strainer before water supply pipeline valves should be 20-40 mesh, while the coarse filtration mesh size for wastewater treatment systems should be 10-20 mesh.

Practical Cases and Common Misconceptions in Mesh Selection

1. Analysis of practical case studies

Case 1: A Central Air Conditioning Cooling Water System

-System parameters: Water supply medium, temperature 25-35℃, pressure 0.6MPa, flow rate 100m³/h

-Protected components: butterfly valves and circulating water pumps;

-Selection criteria: The circulating water pump impeller can handle impurities up to 200μm, while the butterfly valve seal surface withstands impurities up to 300μm. The medium is low-viscosity clear water with minimal impurities. The selection complies with GB 50268-2019.

-Final selection: 60-mesh 304 stainless steel basket Strainer with an effective pore size of approximately 250μm, which meets equipment protection requirements while preventing excessive pressure drop.

Case 2: A Hydraulic System High-Pressure Oil Circuit

System parameters: The medium is No.46 anti-wear hydraulic oil, operating at 40-60°C, 16MPa pressure, and 50m³/h flow rate.

Protected components: solenoid directional control valve and relief valve;

Selection criteria: Electromagnetic directional control valve with a throttling clearance ≤30μm, requiring filtration precision ≤20μm; medium with moderate viscosity and low impurity content; high-pressure operation requires a high-strength Strainer screen.

Final selection: 300-mesh Hastelloy sintered Strainer screen (effective pore size ~40μm), with an integrated backwash system to prevent clogging and maintain stable system pressure.

2. Common mistakes in model selection

Myth 1: The higher the mesh size, the better

Some industry practitioners mistakenly assume that higher mesh sizes equate to better filtration performance, leading to the indiscriminate use of 200-mesh or higher Strainer. This results in excessive system pressure drop (e.g., a 0.05 MPa pressure drop in the original system increases to 0.3 MPa with a 300-mesh filter), higher energy consumption, and frequent filter clogging, which significantly increase maintenance costs.

Misconception 2: Selecting models based solely on mesh count while ignoring the actual aperture size

In a project, the selection team chose a 100-mesh Strainer as per the manufacturer’s specifications. However, due to the oversight of the wire diameter parameter, the purchased Strainer had a wire diameter of 0.15mm, resulting in an actual pore size of 100 μm, which hindered fluid flow. The correct selection should have been a 100-mesh Strainer with a 0.1mm wire diameter, yielding a 150μm pore size that meets both precision requirements and flow efficiency.

Misconception 3: The Influence of Medium Viscosity Is Not Considered

In a heavy oil transportation system, a 100-mesh Strainer was used. Due to the high viscosity of the heavy oil (kinetic viscosity ≥100 mm²/s at 20°C), the filter became severely clogged, preventing normal oil supply. After replacing it with a 40-mesh Strainer, the clogging issue was resolved without affecting the normal operation of downstream valves.

Suggestions on Strainer Maintenance and Mesh Adjustment

1. Key aspects of Strainer maintenance

-Regular cleaning: Based on the system’s impurity levels, disassemble and clean the Strainer screen periodically to prevent clogging caused by impurity buildup. High-mesh Strainer should be cleaned every 1-2 months, while low-mesh Strainer should be cleaned every 3-6 months.

-Inspect for damage: During cleaning, check the filter screen for any damage or deformation. Replace it immediately if found damaged to prevent unfiltered media from entering downstream equipment.

-Replacement cycle: The typical service life of filter screens ranges from 1 to 3 years. For media with strong corrosiveness or high impurity content, the replacement cycle should be shortened.

2. Practical scenarios for mesh adjustment

If the Strainer screen becomes clogged frequently (e.g., more than once weekly) and the system permits, consider reducing the mesh size (e.g., from 100 to 60) or adding a pre-stage coarse Strainer.

If downstream equipment frequently experiences wear or leakage due to impurities, increase the mesh size (e.g., from 60 to 100) or implement multi-stage filtration.

If medium properties change (e.g., increased viscosity or impurity content), recalculate the mesh size based on updated medium parameters to ensure filtration efficiency aligns with system requirements.

The selection of filter mesh size for valve Strainer is a critical aspect in fluid system design and operation. The key lies in “precise matching” -based on the impurity tolerance threshold of the protected equipment, combined with medium characteristics, system conditions, industry standards, etc., to find the optimal balance between filtration accuracy and flowability, as well as maintenance costs.

In practice, avoid blindly pursuing a high mesh size; focus on the mesh size and aperture, material, and Strainer structure, and coordinate their adaptation; and strengthen filter screen maintenance to give full play to the valve Strainer’s “safety guard” role and ensure the system’s stable and efficient operation.

FAQs about Valve Strainer mesh size selection, based on real industrial questions and the key points from the article above:

Q1: What does “100 mesh” actually mean? Is it the same as 100 μm hole size? A: No. “100 mesh” means there are 100 openings per linear inch (25.4 mm). The actual hole (aperture) size is smaller than 25400 μm ÷ 100 = 254 μm because the wire itself takes up space. For standard 304 stainless steel 100-mesh with 0.1 mm wire, the real aperture is ~150 μm, not 100 μm.

Q2: People say “the higher the mesh number, the finer the filtration”. Is it always better to choose a higher mesh? A: Definitely not. Higher mesh = smaller holes = higher filtration precision, but also higher pressure drop, faster clogging, and higher risk of screen damage (especially under high pressure/flow). In many systems (cooling water, heavy oil, sewage, etc.), 20–60 mesh is the correct and most economical choice. Blindly using 200+ mesh is one of the most common and expensive mistakes.

Q3: How do I quickly decide the minimum mesh for my application? A: Use the “impurity tolerance threshold” of the most sensitive downstream component:

- Ordinary gate/globe valves → 60–100 mesh

- Ball/butterfly valves → 100–150 mesh

- Control valves, regulating valves, servo valves → 200–300 mesh or finer

- Centrifugal pumps → usually ≥40–80 mesh (check manufacturer)

- Precision plunger pumps, flow meters → ≥100–200 mesh Choose the mesh that makes the aperture ≤ the maximum particle size the equipment can tolerate.

Q4: For the same mesh number, why do different manufacturers have different actual micron ratings? A: Because wire diameter varies. Thicker wire → smaller actual aperture at the same mesh count. Example: 100 mesh + 0.10 mm wire → ~150 μm opening 100 mesh + 0.15 mm wire → ~100 μm opening Always ask the supplier for the actual micron rating or check the wire diameter.

Q5: In which situations must I absolutely not use high-mesh (≥200 mesh) Strainers?

- High-viscosity media (heavy oil, asphalt, glue, etc.)

- High-impurity media without pre-filtration or backwash (raw sewage, circulating cooling water with algae, etc.)

- High-pressure systems ≥10 MPa without reinforced/sintered screens

- Systems that cannot be shut down for frequent cleaning

Q6: Y-type Strainer or Basket-type — does the structure limit the maximum mesh I can use? A: Yes.

- Y-type: small filtration area → easy to clog → generally not recommended above 100–120 mesh (many manufacturers limit to 80–100 mesh max).

- Basket-type or T-type: large filtration area → can safely use 150–300 mesh or higher.

Q7: How often should the Strainer be cleaned at different mesh counts? Approximate guideline (adjust according to actual differential pressure monitoring):

- 10–40 mesh → clean every 3–6 months

- 60–100 mesh → clean every 1–3 months

- 150–300 mesh → clean or backwash every 1–4 weeks Install a differential pressure gauge or switch; when ΔP rises 0.05–0.1 MPa above clean state, clean immediately.

Q8: Can I directly replace a 60-mesh Strainer with a 200-mesh one in an existing system? A: Almost never without consequences. You will usually get:

- Sharp increase in pressure drop (pump energy consumption ↑)

- Frequent clogging → frequent maintenance or production interruption

- Possible screen rupture under the original flow/pressure Correct approach: increase Strainer body size (e.g., DN50 pipeline uses DN80 or DN100 Strainer body), or add coarse pre-filter + fine filter in series, or change to automatic backwash type.

Q9: Which material allows the finest mesh while remaining strong? A: 316L stainless steel plain weave → up to ~500 mesh Sintered 316L or Hastelloy powder → 200–500 mesh with very high strength (commonly used in high-pressure hydraulic and aviation systems).