What most people don’t mention is that a British Standard Pipe Taper (BSPT)1/2 válvula de bola port and an American National Pipe Taper (NPT) plug will never seal well. The 5-degree difference in thread angle leaves tiny gaps that can cause major failures.

I saw this happen at a Texas refinery in 2019. The maintenance crew used an NPT blanking plug on a UK-made control valve during a turnaround. The pressure test passed at 60 PSI, and the system started up. Seventy-two hours later, the plug blew out at 3 AM, spraying 400 gallons of hydraulic oil across the pump room.

The result was $12,400 in damage and 18 hours of downtime.

Before diving in, here’s how this guide will help you: it will show you how to identify each thread type quickly, explain why they aren’t compatible, and describe the one situation where mixing them is safe. Understanding these points will help you avoid costly mistakes.

What Makes BSPT and NPT Incompatible

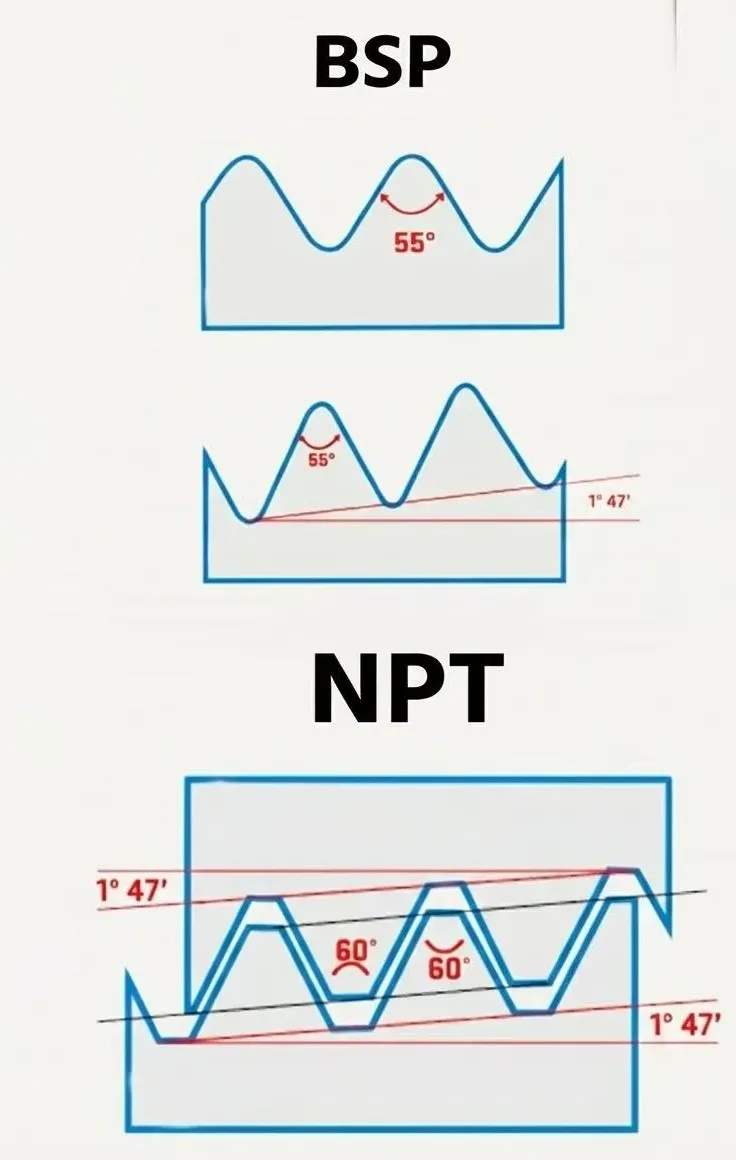

The 5-Degree Problem

NPT threads: 60-degree angle BSPT threads: 55-degree angle

That 5-degree difference means thread flanks never mate properly. The gap measures 0.003″ to 0.007″ depending on size. At 500 PSI, that’s enough to make any fluid weep past the sealant.

I tested this in our shop. Use a 1/2″ NPT plug, apply 3 wraps of PTFE tape, and thread it into a 1/2″ BSPT port—torque to 25 ft-lbs (correct for this size). Pressurize to 200 PSI with water.

Result: Visible weeping within 5 minutes. Pressure dropped to 185 PSI in 30 minutes.

The angle mismatch causes the threads to touch at points rather than along their flanks. This puts all the sealing force on the tops of the threads, which crushes the PTFE tape unevenly. The valleys stay empty, creating easy paths for fluid to leak through.

Thread Pitch: The Hidden Difference

Thread pitch varies between standards, but not consistently:

| Size | NPT TPI | BSPT TPI | Match |

|---|---|---|---|

| 1/4″ | 18 | 19 | ❌ Different |

| 1/2″ | 14 | 14 | ✅ Same |

| 3/4″ | 14 | 14 | ✅ Same |

| 1″ | 11.5 | 11 | ❌ Different |

Notice that 1/2″ and 3/4″ sizes have the same pitch. This makes some people think they are interchangeable, but they are not. The angle mismatch still ruins the seal even if the pitch matches.

Sealing Mechanism: Root vs. Flank

NPT relies on interference fit at thread roots. As you tighten, the male taper wedges into the female taper, creating the seal. Requires 1.5-2 turns past hand-tight.

BSPT uses flank-to-flank contact. The 55-degree angle seats along the entire length of the thread. Needs only 1-1.5 turns past hand-tight.

Here’s the practical difference: If you use NPT torque values on BSPT fittings, you can crack the fitting. I’ve taken apart brass BSPT elbows that broke at the hex because someone over-tightened them.

How to Identify NPT vs BSPT in 30 Seconds (No Tools)

You’re in the field without a thread gauge. Need to identify that the fitting is fast.

Method 1: Thread Count Test

Find the straight section of the fitting (the first 2-3 threads). Count threads in exactly 1 inch.

- 27-28 threads = 1/8″ size (NPT=27, BSPT=28)

- 18-19 threads = 1/4″ size (NPT=18, BSPT=19)

- 14 threads = 1/2″ or 3/4″ (identical for both standards, so use Method 2)

Mark the start thread with a Sharpie, count while sliding a thumbnail along. The 1-thread difference is visible in good light.

Method 2: Check Manufacturer Markings

Look for stamped or cast codes:

NPT indicators: “NPT”, “NPTF”, “ASME B1.20.1”, “MIP” BSPT indicators: “BSPT”, “PT”, “R”, “BS 21”, “EN 10226”, “DIN 2999”

Instrumentation fittings have small stamps on the hex flats. Bring a wire brush because years of paint can hide these markings.

I found a mystery fitting on a compressor once. Wire-brushed the hex, found “R 1/2” stamp—ISO external BSPT and saved us from ordering the wrong replacement.

Method 3: Thread “Sharpness” Feel

Run your thumbnail perpendicular across the threads.

BSPT feels sharper because the 55-degree angle focuses pressure on your nail. NPT feels blunter since the 60-degree angle spreads the pressure out.

This is subjective. Calibrate by first feeling a known NPT and BSPT fitting. After 15 years, I can tell the difference blindfolded.

BSPT vs NPT: Technical Comparison

| Parameter | NPT | BSPT |

|---|---|---|

| Thread Angle | 60° | 55° |

| Taper Rate | 1:16 | 1:16 |

| Sealing Method | Thread interference | Thread flanks |

| Sealant (typical) | PTFE tape (3-5 wraps) | PTFE tape (2-4 wraps) |

| Torque (1/2″) | 25-30 ft-lbs | 18-22 ft-lbs |

| Geographic Use | Americas, Asia | UK, Europe, Australia |

| Oil & Gas Standard | API 6D | BS 5351, ISO 10497 |

| Standards Reference | ASME B1.20.1 | ISO 7-1, EN 10226-1 |

Where Each Standard Dominates

NPT Territory:

- North America (all refining, petrochemical per API standards)

- Middle East oil & gas (Saudi Aramco, ADNOC)

- Asia-Pacific (South Korea, Japan, Taiwan, China)

BSPT Territory:

- United Kingdom, Ireland

- Continental Europe (Germany, France, Netherlands)

- Australia, New Zealand, India

I worked on a Saudi refinery where Italian contractors submitted BSPT valves. Aramco rejected 400 valves at receipt. $2.1 million re-order. The RFQ clearly stated “API 6D, NPT threads.”

When Can You Mix NPT and BSPT? (The Exception)

The ONLY Acceptable Scenario

Emergency repair. Correct fitting won’t arrive for days. The system needs to run.

Required conditions (ALL must be true):

- Pressure ≤150 PSI (preferably ≤100 PSI)

- Non-critical service (such as instrument air, cooling water, or drain ports; never use for steam, hydrogen, or flammable fluids)

- Temperature <200°F

- Low vibration environment

- Temporary installation (<30 days until replacement)

Installation Procedure for Emergency Mix

- Inspect threads: Any damage = stop. Angle mismatch won’t tolerate imperfect threads.

- Use anaerobic thread sealant (Loctite 567), not just PTFE tape. Liquid fills the angle-mismatch gaps better.

- Add PTFE over sealant: 5 wraps, 50% overlap, high tension. Redundant sealing.

- Torque to 70% of standard: For 1/2″ = 18-20 ft-lbs instead of 25-30. Compress sealant without crushing threads.

- Pressure test at 1.5x operating pressure for 30 minutes. Any weeping = abort.

- Inspect daily for the first week. Check for moisture, vibration, and discoloration.

What Will Definitely Fail

Never mix NPT and BSPT in:

- Steam service (any pressure): thermal cycling wears out mismatched threads

- Hydraulic systems (over 500 PSI): the angle mismatch cannot hold pressure

- Flammable or toxic fluids: the risk is too high

- Sizes over 1 inch: larger threads make the gap worse

- NPTF dryseal threads: these require a metal-to-metal seal

I watched someone use an NPT plug in a BSPT steam trap. 150 PSI saturated steam. Installed Friday. Monday morning, it was shrieking—thermal cycling walked the plug out 1/8 turn.

The Three Warning Signs Before Failure

When NPT and BSPT are mixed, failure is progressive. Watch for:

1. Weeping Within 24-48 Hours: You may see slight moisture at the base of the connection. It is not dripping; it is just damp. The PTFE tape is breaking down under uneven pressure. Do not re-tighten, as that will make it worse. Replace the fitting with the correct standard.

2. Vibration Changes: Mismatched threads don’t seat evenly. The fitting rocks microscopically under pressure cycling. Place your hand on the body—you’ll feel a slight buzz that matches the threads that don’t produce.

3. Discoloration Around Connection Brass fittings show dark rings around the first threads when an angle mismatch causes fretting. Stainless shows polished rings from micro-rotation under pressure pulses.

In the Texas refinery incident, the threads work-hardened under vibration—micro-cracks formed at thread roots. At 72 hours, cracks propagated enough that the plug ejected at normal operating pressure (450 PSI).

Root cause: Only the first 2 threads were actually engaged due to angle mismatch. Those threads carried 100% of the load instead of being distributed across 4-5 threads.

FAQ: BSPT vs NPT

Can I use NPT fittings on BSPT threads?

No, not for permanent installation. The 5-degree angle mismatch (60° vs 55°) prevents proper sealing. Threads engage but create micro-gaps that leak within 24-48 hours under pressure.

Emergency exception: Low pressure (≤150 PSI), non-critical service, anaerobic sealant plus PTFE, daily inspection, replace within 30 days.

What happens if you mix NPT and BSPT?

The thread flanks don’t mate properly. This causes:

- Immediate: Uneven sealant compression, micro-gaps

- 24-48 hours: Weeping as sealant degrades

- Weeks to months: Thread work-hardening, micro-cracks

- Eventual failure: Plug ejection or catastrophic leak

Timeline depends on pressure and vibration. I’ve seen failures in 72 hours (high pressure) and limping installations for years (low-pressure drains).

How many threads per inch for 1/2″ NPT vs BSPT?

Both have 14 threads per inch. Identical pitch but different angle (60° NPT, 55° BSPT). This is why people mistakenly think they’re interchangeable.

For 1/4″ size: NPT=18 TPI, BSPT=19 TPI (easier to distinguish by counting).

Which is better, NPT or BSPT?

Neither is objectively better; they are simply regional standards.

Choose based on:

- Geographic location (use local standard)

- Governing code (API→NPT, BS/EN→BSPT)

- Existing plant infrastructure (don’t mix standards)

I specify NPT for North American projects and BSPT for European projects. Trying to standardize globally creates supply chain problems.

How to seal BSPT threads properly?

- Clean threads: Brake cleaner, dry completely

- Apply sealant: PTFE tape 2-4 wraps clockwise, starting 2 threads from the end, 50% overlap.

- Hand tighten: 3-4 turns until firm resistance.

- Torque: 1/4″=12-15 ft-lbs, 1/2″=18-22 ft-lbs, 1″=30-35 ft-lbs

- Don’t over-torque: BSPT needs less torque than NPT. One turn past hand-tight is usually sufficient.

Conclusion: Always match your threads, or you will pay the price

The difference between BSPT and NPT isn’t academic. It’s why that plug ejected in Texas and sprayed 400 gallons of hydraulic oil.

Your action plan:

- Identify before installing: Use the thread count or marking check. Don’t assume.

- Specify explicitly: Write “NPT” or “BSPT” in every equipment spec. Never use “equivalent” language.

- Never mix in critical service: Steam, high-pressure (>500 PSI), toxic, or flammable fluids require matched threads.

- Stock the right fittings: Mixing standards to save $15 costs $12,000 when it fails.

Engineers who learn this difference avoid chasing leaks during startups. Those who ignore it end up spending commissioning time with a wrench, tightening fittings that will never seal.

Check your project’s governing code. API = NPT. BS/EN = BSPT. When in doubt, check the detail drawing.