What is 3 way ball valve?

3 way ball valve is a commonly used valve for medium diversion, convergence and direction change. Similar functions include three-way regulating valve, three-way plug valve, three-way globe valve, three-way diaphragm valve, three-way butterfly valve, etc.

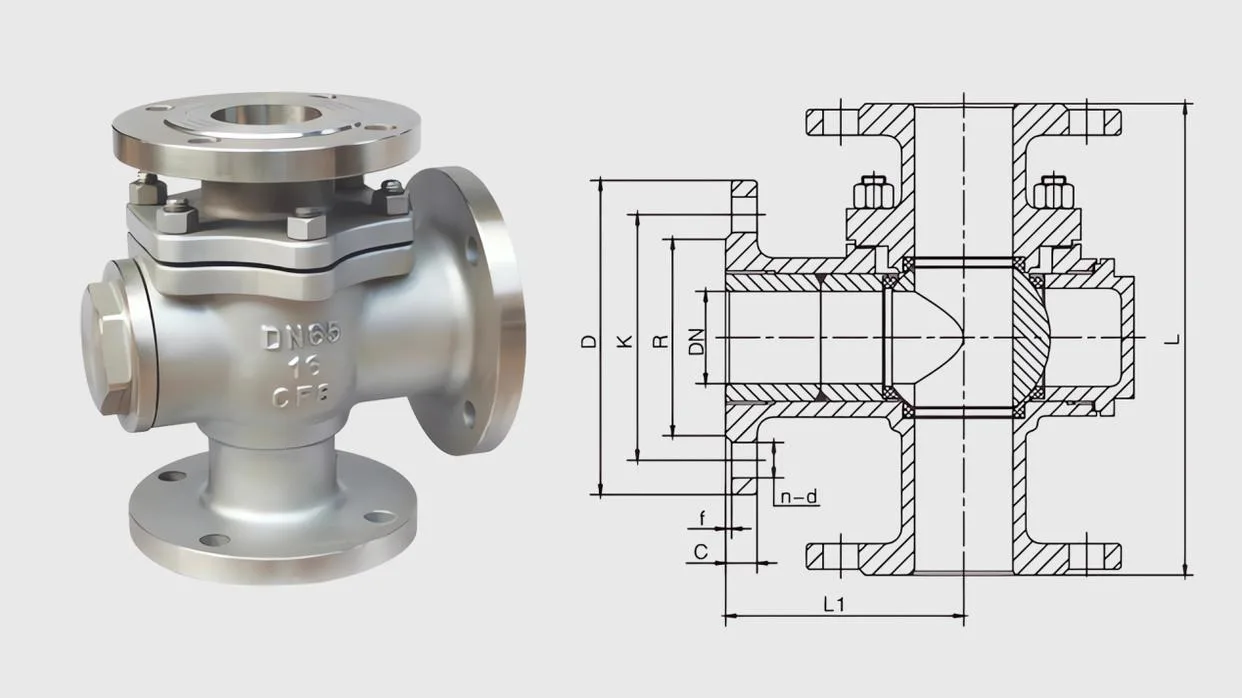

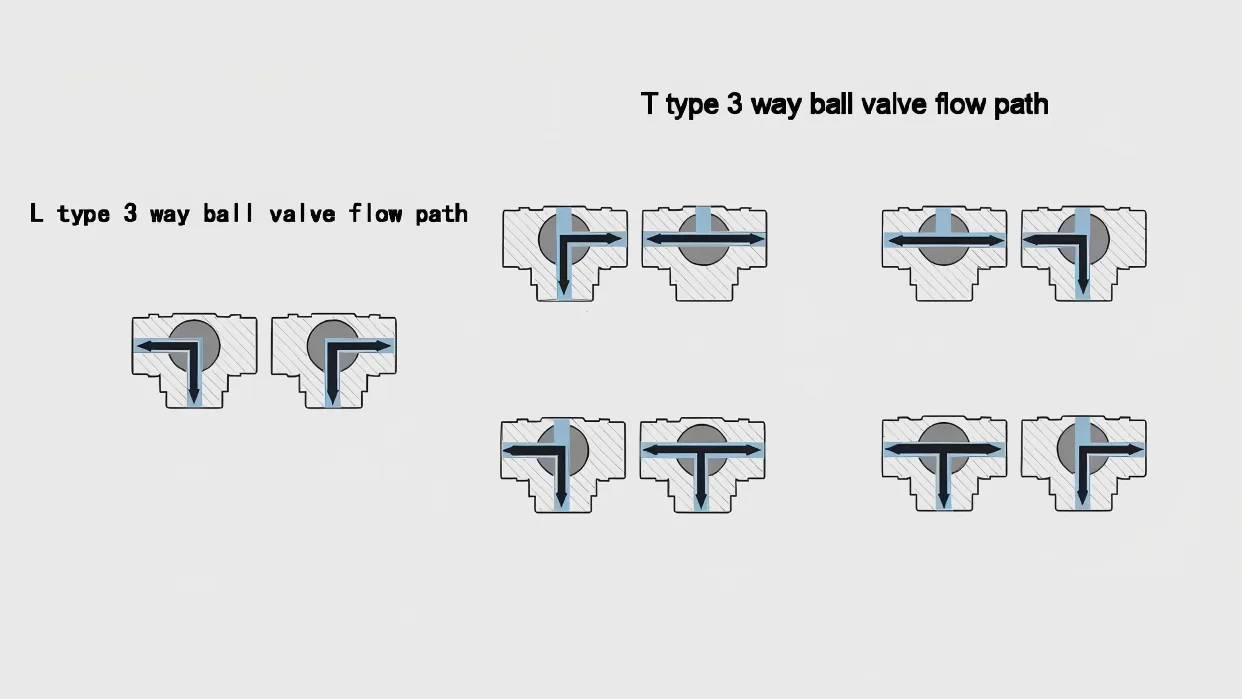

Three-way ball valves are classified as L-type or T-type based on their valve body inlet/outlet configurations.

The adjacent flow channel openings of the L-shaped valve body are 90 degrees, which is a common one. The characteristic of the valve body is that two of the flow channel openings are on the same axis, and the third flow channel opening is perpendicular to this axis.

It is classified into two types based on the shape of the ball core flow channel: L-type and T-type.

The L-type three-way ball valve enables bidirectional flow switching between two perpendicular pipelines. It maintains separate flow paths without merging or diverging them, thus preventing combined or split operations. Featuring dual-seat sealing design, this valve offers low torque requirements and simplified assembly and maintenance.

The T-type three-way ball valve enables three-way mixing, splitting, and directional switching of media. Its T-shaped configuration allows interconnection of all three flow channels or selective communication between two of them, offering enhanced functionality. Featuring a four-seat sealing structure, this valve demonstrates greater torque capacity than the L-type three-way ball valve of equivalent diameter. When using pneumatic or electric actuators, ensure the selected torque specification matches the valve’s requirements to prevent under powered operation.

| characteristic | L-port valve | T-port valve |

| Flow channel shape | L form | T form |

| major function | Switch direction | Flow, mix, switch |

| Flow Possibilities | Two ports are connected | Two or three ports are connected |

| application scenarios | Simple Fluid Switch | Complex fluid distribution and mixing |

| Operation complexity | Simple (90° switch) | Slightly more complex (multi-directional configuration) |

| prime cost | lower | higher |

| usability | Single path selection | Multi-path allocation or hybrid |

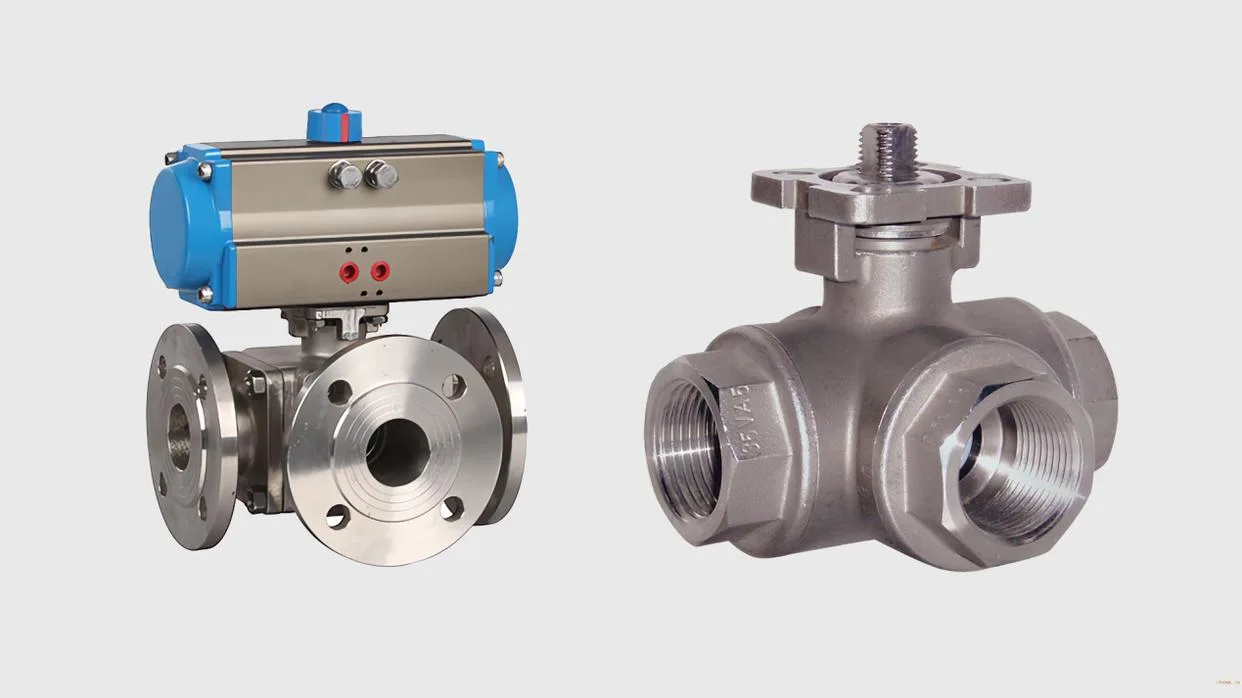

The working principle of three-way ball valve also involves its driving mode:

Operation mode: The valve can be operated by hand (mechanical valve) or by actuator (electric ball valve). The motor is responsible for opening, closing, metering and distribution.

Operation selection: The choice between manual or electric valves depends on system requirements. Electric valves are commonly used in unattended applications and can be operated remotely.

Position holding: Electric ball valves usually do not require power to hold their position, unlike solenoid valves.

In summary, the basic concept of a three-way ball valve is its three-port design and the mechanism of rotating the ball to control the flow direction, and all its important features are concentrated in the L-shaped and T-shaped port configuration, which is the key to determine whether the valve can mix, split or switch

The general function and advantages of three-way ball valve

The three-way ball valve is the most widely used type of multi-port ball valve, and its biggest feature is its versatility

They provide more flow control options than standard two-way valves.

The general functions that the three-way ball valve can perform include:

- Switch flow: Switch fluid flow between two positions.

- Fluid mixing: Mix fluids from two locations.

- Traffic diversion: Implement traffic diversion.

- Redirect: Used for applications requiring traffic redirection.

- Isolation control: Stop the flow from one place, but continue the flow to another place.

- Complete shutdown: Capable of fully stopping or cutting off the flow, though limitations vary depending on port type.

- Application scenario classification based on port type

The functionality and application scenarios of a three-way ball valve are entirely determined by the type of bore in its internal ball—either L-shaped or T-shaped.

L-port valve: Splitter service

The L-type port valve is also known as a diverter valve

Its core function is to divert traffic from one port to another

The L-shaped structure means that the fluid flows at 90 degrees between the side ports.

Main functions and application scenarios of L-type port:

- Traffic switching: for traffic splitter services.

- Switch source/destination: Suitable for applications that need to switch between two sources or destinations without mixing.

- Pump switching: Switch between one pump and another separate pump.

- Tank switching: Switch flow between two storage tanks 7.

- Cooling system: used to divert flow from free cooling to a cooler, or between a cooling system or heat exchange.

- Switch control: Simple switch control between two destinations.

It should be emphasized that the L-type valve’s construction does not permit all three ports to be opened simultaneously.

T-port valve: mixing and splitting

The T-port valve is designed for versatility, with its T-shaped orifice enabling flow in multiple directions.

The main functions and application scenarios of T-port:

- Fluid mixing: Combine two different fluid sources into a single outlet.

- Traffic splitting: Split traffic from a single entry point to two exits.

Bidirectional flow: Opposite flow is also possible, allowing a source to flow to two places at the same time.

- Direct flow: allows fluid to flow between any two ports, including direct flow.

- Multi-tool operation: Run multiple tools from the same fluid source. For example, in a paint system, a T-valve can direct a single spray gun to one position or supply two spray guns simultaneously when all three ports are open, achieving operational flexibility.

T-type valves are most suitable for systems requiring mixing, diversion, or straight-through flow.

Principles for the selection of functions

Identifying the required primary functions and application scenarios is key to selecting the right valve type:

- For configurations requiring directional flow switching between two outlets or two inlets without mixing, select the L-type valve.

- Select a T-type valve if the system requires mixing, diversion, or straight-through flow.

- To fully disable the function, users must verify whether the specific L-type or T-type design supports full shutdown, as standard T-type valves typically lack this capability.

Top Suppliers for 3 Way Ball Valves in 2025

| Supplier | type | Materials & Sizes | RFQ Process | Website |

| Gemini Valve (Made in USA, NH) | L/T-port, diverter/mixer; self-sealing stems; custom designs. Actuated options available. | Carbon steel, stainless 316; 1/4″–4″. Up to 1000 PSI. | Online quote form; 1-hour response. Custom engineering support. | geminivalve.com |

| Kinvalve (Global supplier, 18+ years) | Flanged/threaded/tri-clamp; L/T-port; lockable handles. Dismountable for multi-port configs. | Stainless steel (carbon steel optional); 1/2″–4″. ANSI B16.5 flanges. | Contact form or email for specs; actuator-ready platforms. | kinvalve.com |

| Valtorc International | Direct-mount for actuation; high-cycle life; blow-out-proof stems. | 316 stainless; 1/4″–2″ NPT. 150 PSI WSP, up to 475°F. | Quote request via site; API 598 tested. | valtorc.com |

| Tops valve | L-port with mounting pad; T-port with mounting pad; | 316 stainless, WCB; 1/4″–10″ | Quote request via site; API 598 tested. | Tops-valve.com |

| Harrington Industrial Plastics | Universal series (manual/actuated); horizontal/vertical mounts. | CPVC, PP, PVC, PVDF; DN10–DN50. | Product selector + quote request; GF Piping Systems integration. | hipco.com |

| Gosco Valves | 3-way diverters; cryogenic/extreme pressure options. Bottom-entry designs. | Custom alloys; various sizes. | Dedicated quote form per config; auto-sent to sales. | goscovalves.com |

| M.A. Stewart & Sons | ISO mounting pads; industrial/plumbing grades. Actuator options. | Stainless steel, brass; standard sizes. | Contact for quotes; bulk industrial focus. | mastewart.com |