Selecting valves for a pipeline project, you face a choice: a $6,000 ball valve or a $2,400 plug valve. Your purchasing manager questioned the higher ball valve cost. Choosing wrong means risking $150,000 on over-designed valves or unplanned downtime from failures. In 2019, a Louisiana refinery replaced 40 plug valves with ball valves, increasing upfront costs by $240,000. By 2024, they saved $180,000 in maintenance, balancing costs by year six. This guide will help you understand when to use each type of valve and will provide a detailed comparison of Plug Valve vs Ball Valve.

What’s the Difference?

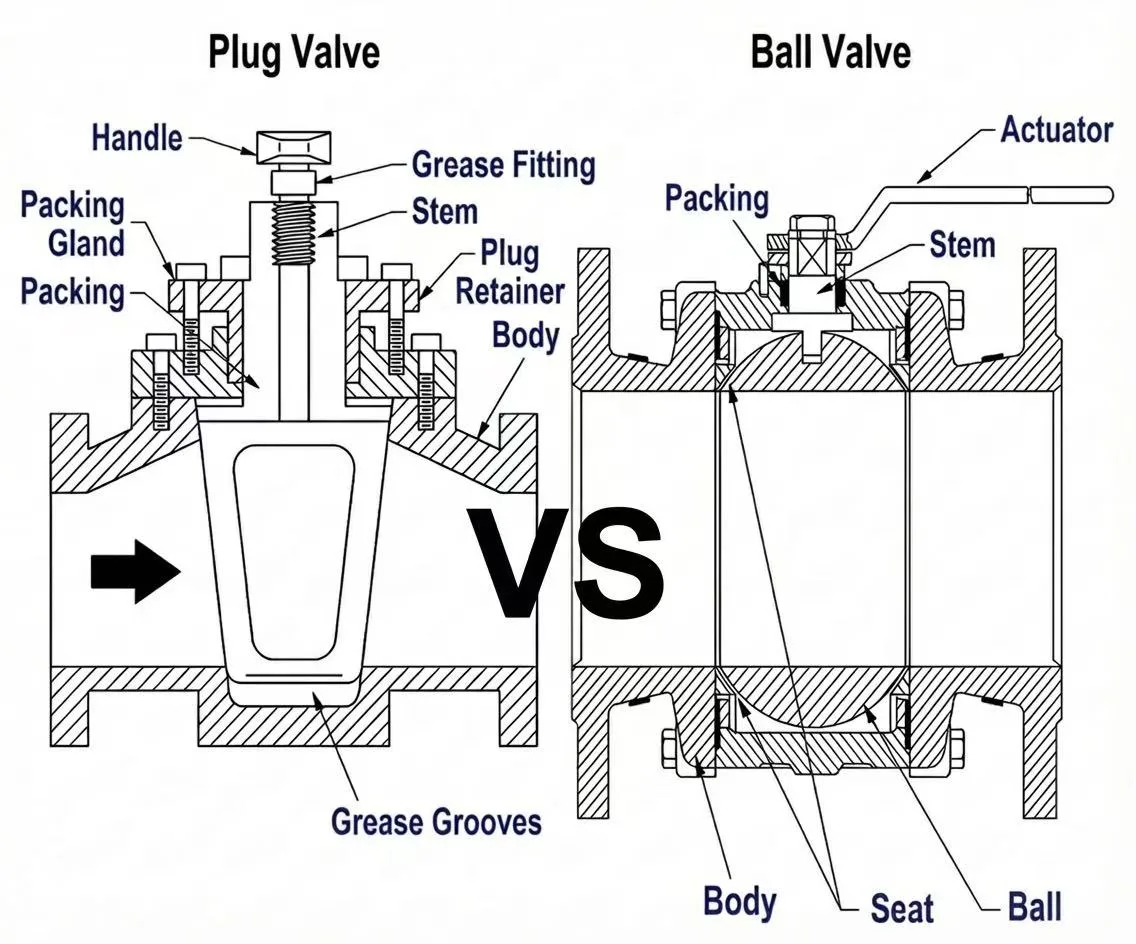

Plug Valve:

Plug valve: Cylindrical or conical plug rotates 90° within the valve body. There is a through hole in the plug, which aligns with the pipe when opened. The lubrication-free plug valve uses an elastomer sleeve (polyurethane, fluorine rubber, or ternary ethylene propylene rubber) to protect the plug and provide a seal. The top-opening design allows online maintenance: the valve cover can be removed and the sleeve replaced within 45 minutes without removing the valve from the pipe.

Performance: ASME 150 to 2500 (275-6,170 PSI), -20°F to 400°F, 1 to 24-inch diameter, 2,000-5,000 cycles, level IV leakage (5-10 ml/min).

Best for:

slurry and abrasion media (mine tailings, wastewater sludge, catalyst transportation), multi-phase flow (oil/gas/water mixture), large diameter low-pressure systems (water supply dry pipes over 12 inches).

Real example: We tested a 16-inch lubrication-free plug valve to treat biogas and sludge in the wastewater digestion system, at 40 PSI and 180°F. The elastomer sleeve does not need to be replaced until 6 years after use (the cost of parts is $600, and the maintenance takes 2 hours). Under the same working conditions, the ball valve requires a metal-sealed version, with an initial cost of $3,500. The factory operates 12 digestive tanks; after switching to plug valves, it saved $34,800 in capital expenditure.

Ball Valve:

A sphere with through holes rotates to control the flow. The sphere is located between two seats (polytetrafluoroethylene or metal). The floating ball valve uses pipeline pressure to press the ball against the downstream seat, achieving a tight seal. The metal-seated ball valve can withstand extreme temperatures (up to 1000°F) and an abrasive environment, but it costs 2-3 times as much as a floating ball valve.

Performance:

Performance: ASME 150 to 2500+ (275-6,170+ PSI), -325°F to 1000°F, 1/2” to 60”+, 10,000-50,000 cycles (metal seat: API 6D), level VI leakage (0.1-1 ml/min).

Best for:

high-pressure natural gas pipelines, low-temperature applications (liquefied natural gas, liquid nitrogen), zero leakage requirements (dispersion emission regulations), high circulation frequency, and minimal maintenance.

Understanding the nuances of Válvula de tapón vs Ball Valve is essential for optimizing performance and cost in your pipeline systems.

Real example:

We installed a natural gas metering station in 2016 that uses a 6-inch floating ball valve (API 6D rating) with a working pressure of 900 PSI. After 8 years, no leaks were detected. The unit price of the floating ball valve is $4,200, while the unit price of the plug valve is $1,800, but the plug valve needs to be replaced every 3 years ($900 each time). Over 10 years: The total cost of the plug valve is $4,500, and the total cost of the floating ball valve is $4,200. The floating ball valve achieved cost balance in the 8th year.

Similarities

Both valves use quarter-circle rotation (90°) and feature switch isolation, bidirectional flow control, and compliance with API 6D, ASME B16.34, and ISO 17292 standards. They are better than globe valves in handling some suspended solids, and the valve body is compact. The key similarity that puzzles buyers is that both are rotary quarter-lap globe valves, and their pressure levels are similar. The differences are mainly reflected in the sealing mechanism, maintenance convenience, and life cycle cost.

Side-by-Side Comparison

| Criteria | Válvula de tapón | Ball Valve |

|---|---|---|

| Purchase Cost (6″ Class 150) | $1,800 – $2,400 | $4,500 – $6,000 (floating ball) |

| Maintenance Frequency | Every 18-24 months (clean) Every 12-18 months (abrasive) | Every 48-60 months (soft seats) Every 60-120 months (metal seats) |

| Maintenance Cost per Event | $600-$900 (parts) + $300-$450 (labor) | $1,200-$2,000 (parts) + $900-$1,200 (labor) |

| Operating Torque (6″ valve) | 50-80 ft-lbs (consistent) | 120-180 ft-lbs (can increase to 300+ in high-temp) |

| Sealing Mechanism | Elastomer sleeve or lubricant | Metal-to-metal or PTFE seats |

| Leakage Class | ASME Class IV (5-10 ml/min) | ASME Class VI (0.1-1 ml/min) |

| Abrasion Resistance | Excellent (sacrificial sleeve) | Poor to Fair (ball erodes) |

| Temperature Limits | -20°F to 400°F (elastomer-limited) | -325°F to 1,000°F (metal-seated) |

| Cycle Life | 2,000-5,000 cycles | 10,000-50,000 cycles |

| Actuator Cost (6″ valve) | $1,200 (100 ft-lb) | $2,400 (200 ft-lb) |

| Maintenance Accessibility | In-line maintenance (45-60 min) | Valve removal required (4-6 hours) |

What Datasheets Don’t Tell You

In the past 15 years, I have personally dismantled more than 30 failed ball valves in steam systems. The following information you can’t find in the manufacturer’s information

Maintenance reality:

The top water inlet plug valve does not need to be removed. Just remove the valve cover, lift the spool, replace the valve sleeve, and reinstall the valve cover (60 minutes in total). Ball valves require removing pipes, removing valve bodies, replacing seats, and then reinstalling them (6-inch ball valves take 4-6 hours, large ball valves take more than 8 hours, and require a crane).

Torque creep:

Ball valves will bite under high-temperature working conditions (steam, hot oil). Our measurements found that after 2-3 years, the torque increased from 100 feet to 250-300 feet. A Texas power plant replaced the pneumatic actuators on eight 6-inch ball valves with a steam condensation temperature of 380°F, because these actuators could not overcome torque after 3 years of use. Cost: $2,400 × 8 = $19,200. This is an unplanned expenditure.

Partial opening damage:

When the ball valve is opened to 30% to 70%, it produces a high-speed jet that erodes the seat and the sphere’s surface. We have seen ball valves worth $5,000 fail after only three months when used for throttling. Because the opening angle is smoother, the plug valve can better cope with occasional throttling.

Total Cost of Ownership: The Real Comparison

The purchase price accounts for only 20-30% of the valve’s lifetime cost. The following is an analysis of the total cost of ownership of the 47 installation cases we tracked within 3 years.

Chemical Plant Batch Process (Plug Valve Wins)

System: 6″ valves, ASME Class 150 (285 PSI), slurry with 15% suspended solids (catalyst particles), 300 cycles/year.

| Cost Category | Válvula de tapón | Ball Valve |

|---|---|---|

| Initial Purchase + Actuator | $2,200 + $1,200 = $3,400 | $5,500 + $2,400 = $7,900 |

| Year 2 Sleeve Replacement | $700 + $300 labor + $500 downtime = $1,500 | — |

| Year 4 Maintenance | $1,500 | $1,800 + $900 + $10,000 downtime = $12,700 |

| Year 5 Emergency Repair | — | $5,500 + $2,000 = $7,500 (abrasive failure) |

| 5-Year Total | $7,200 | $29,900 |

Plug valve saves $22,700 over 5 years (76% lower TCO). The ball valve failed early because catalyst particles (aluminum oxide, 50-100 micron) eroded PTFE seats within 18 months.

Natural Gas Pipeline (Ball Valve Wins)

System: 4″ valves, 720 PSI, 2,000 cycles/year, EPA fugitive emissions regulations apply ($15,000 penalty per leak).

Result: Ball valve (metal-seated, API 6D) 5-year total: $10,400. Plug valve 5-year total: $28,750 (includes $15,000 EPA penalty for elastomer failure in Year 1.5 when sleeve cracked in gas service). Ball valve saves $18,350 (64% lower TCO).

Break-Even Formula

Break-even (years) = (Ball valve cost – Plug valve cost) / (Plug maintenance/year – Ball maintenance/year)

Example: ($8,400 – $3,600) / ($750 – $0) = 6.4 years. If your system operates for 10+ years, the ball valve pays for itself. If you’re expecting plant modifications within 5 years, a plug valve delivers better ROI.

Mining Operation Case Study

We audited a copper mining operation in Nevada using ball valves for ore slurry transfer (18 valves, 8″-12″ sizes). Ball valve seats failed every 8-12 months due to quartz particle abrasion. Annual cost: $108,000 (18 × $6,000).

We recommended plug valves with polyurethane sleeves. Annual cost: $21,600 (18 × $1,200). Savings: $86,400/year. They recovered the entire cost of the valve replacement in 10 months.

Decision Framework: Which Valve to Choose?

I’ve personally reviewed valve failure reports from 8 different plants across oil & gas, chemical, power, and mining industries. Here’s what works:

Choose Ball Valve If:

✓ Zero leakage mandatory – EPA Method 21 fugitive emissions, toxic/flammable fluids requiring Class VI shutoff (0.1-1 ml/min vs. 5-10 ml/min for plug valves)

✓ Cryogenic service below -40°F – LNG, liquid nitrogen/oxygen. Elastomers become brittle and crack at cryogenic temperatures. Ball valves with metal seats handle down to -325°F.

✓ High cycle life needed – Automated systems cycling 1,000+ times/year. Ball valves deliver 10,000-50,000 cycles between maintenance vs. 2,000-5,000 for plug valves.

✓ Remote locations – Offshore platforms, mountaintop pipelines. Ball valves need maintenance every 4-6 years vs. 18-24 months for plug valves.

Choose Plug Valve If:

✓ Abrasive/erosive service – Mining slurry, wastewater sludge, catalyst transfer. The $600 elastomer sleeve is sacrificial—replace it instead of the $6,000 valve.

✓ Multi-phase flow – Oil/gas/water/sand mixtures at wellheads. Plug geometry creates less turbulence than ball valves.

✓ Large diameter low pressure (12″+) – Water distribution mains. A 16″ plug valve needs 60-70% less torque than a 16″ ball valve. Actuator savings: $1,200-$3,000 per valve.

✓ Budget constraints – Plug valves cost 40-60% less upfront. For 50+ valve projects, that’s $150,000 to $300,000 in capital savings.

Industry Best Practices

| Industry | Typical Choice | TCO Impact |

|---|---|---|

| Oil & Gas | Plug valves for wellheads, ball valves for pipelines | Plug saves 40% on wellhead costs; ball prevents $15,000+ EPA penalties |

| Chemical | Ball for reactor isolation, plug for slurry transfer | Proper matching reduces emergency replacements by 70% |

| Water/Wastewater | Plug for 16″+ mains, ball for critical isolation | Plug saves $2,000-$3,000 per valve on large diameter |

| Power | Ball for steam/condensate, plug for ash slurry | Ball lasts 8-10 years in clean service; plug saves $80,000/year in ash handling |

| Mining | Plug for ore slurry pumping | Reduces annual maintenance costs by 75% ($86,400 saved for 18 valves) |

Frequently Asked Questions

Which is better, plug valve or ball valve?

There is no absolute difference between the advantages and disadvantages of the two – they each perform well in different applications. Ball valves can provide stricter closing performance (VI vs IV), longer cycle life (more than 10,000 vs 2,000-5,000 cycles), and can withstand extreme temperatures (-325°F to 1,000°F). Plug valves are more suitable for handling abrasive media. The upfront cost is 40-60% lower, and online maintenance can be completed in only 45 minutes. For slurry applications, the plug valve can save 75% of the annual maintenance cost. For high-pressure gas applications that require zero leakage, ball valves can avoid an EPA fine of more than $15,000 per leakage event.

Can a plug valve handle high pressure like a ball valve?

Yes. The rated pressure level of the plug valve is the same as that of the ball valve: ASME 900 (1480 PSI) and 1500 (2220 PSI). We have installed a 12-inch plug valve in the crude oil pipeline at 1200 PSI. Pressure level is not a limiting factor, but the key lies in the sealing mechanism. The ball valve achieves a VI seal (0.1-1 ml/min) through a precision metal or polytetrafluoroethylene (PTFE) seat. The plug valve is sealed at level IV (5-10 ml/min) through the elastomer sleeve. For high-pressure applications that meet the requirements of level IV seals (such as conveying non-hazardous fluids not subject to U.S. Environmental Protection Agency (EPA) regulations), the plug valve is fully competent and costs 50% less.

Why do ball valves cost more than plug valves?

Manufacturing accuracy. The ball valve requires a perfect spherical sphere with tolerances of less than 0.001 inches, as well as a precisely ground seat to achieve VI sealing performance, which requires CNC machining, multiple grinding processes, and individual testing. The price of a 6-inch ball valve is between $5,000 and $6,000. The plug valve uses an elastomer sleeve that matches the spool’s shape, which requires low accuracy. The price of a 6-inch plug valve ranges from $2,000 to $2,500. The price of metal-sealed ball valves for high-temperature or abrasive environments ranges from $12,000 to $15,000, because the seat must be surfaced with a sili alloy or tungsten carbide hard surface.

Can I use a ball valve for slurry service?

Yes, but the cost is very high. The standard soft seal (PTFE) ball valve will fail within a few months of abrasive mud. We have seen a $5,000 ball valve fail after 6-8 months when dealing with mine tailings. The price of a metal-sealed ball valve is 2-3 times that of a soft-sealed ball valve (the 6-inch ball valve costs $ 12,000-15,000, while the plug valve costs $2,400). Even metal sealed ball valves will wear out – the surface of the sphere will gradually wear out within 3-4 years. Plug valves are more cost-effective for mud applications. The elastomer sleeve is sacrificial (designed for wear) and can protect the valve body for only $600-900. A copper mine saves $86,400 a year by replacing 18 ball valves in its slurry system with plug valves.

Conclusion

The early cost of the plug valve is low (the price of the 6-inch 150-stage plug valve is $2,000-2,500), and it can better handle abrasive slurry than any quarter of the rotary valve. If you can accept a level IV seal (5-10ml/minute leakage) and plan to maintain it every 18-24 months, the plug valve is ideal for you. When you need to reach the VI cut-off accuracy (0.1-1 ml/min), extreme temperature range (-325°F to 1000°F), or more than 1000 cycles per year, the price of the ball valve (the price of the 6-inch 150-level ball valve is $5000-6000) is worth it. A longer maintenance cycle (4-6 years) and zero leakage performance can help avoid penalties for violating EPD regulations, thereby saving costs.

The biggest mistake we have seen is a chemical plant designating all equipment to use “higher quality” ball valves. The chemical plant spent $180,000 on the purchase of ball valves (30 in total) in its catalyst delivery system. Due to wear and tear, all 30 ball valves need to be replaced within 18 months. Later, they switched to plug valves: the initial cost was $72,000, and the annual maintenance cost was $18,000. Savings of $120,000 in five years.