valve selection for corrosive media

valve selection for corrosive media such as strong acid and alkali is a very important and professional problem. Improper selection will lead to rapid failure of valves, leakage of media, safety accidents, environmental pollution and production interruption.The following are the key points, steps and common valve types for the selection of valves for highly corrosive media to provide you with a systematic selection guide.

Core selection principles

For corrosive media, valve selection must follow the following four core principles:

Corrosion resistance first: the material of the valve must be able to withstand the chemical and electrochemical corrosion of the medium for a long time. This is the most basic and important principle.

Seal reliability: The sealing structure of the valve (including the sealing of the valve seat, valve plate/ball and valve stem) must be able to effectively prevent the leakage of dangerous media, whether internal or external.

Operational safety and convenience: The valve should be easy to open and close, and can adapt to working conditions (such as temperature, pressure, frequency). For high-risk media, remote operation or automatic control is often considered.

Economy: Under the premise of meeting the above requirements, choose the most cost-effective valve, comprehensively consider the procurement cost, maintenance cost and service life.

Selection steps and considerations

Determine the process parameters (selection basis)

This is the starting point for selection and must be made as detailed as possible:

Medium nature: what is the specific acid/alkali? What is the concentration? (for example, 98% concentrated sulfuric acid, 37% hydrochloric acid, 50% liquid alkali). Note: the corrosion varies greatly with different concentrations.

Temperature: the operating temperature, maximum/minimum temperature of the medium.

Pressure: the operating pressure, differential pressure and maximum closure differential of the medium.

Flow and bore: pipe size (DN) and required flow characteristics (regulation or switch).

Operation frequency: whether the valve needs to be opened and closed frequently or always on/off.

Select valve body material (key decision)

The selection of material directly determines the life of the valve.

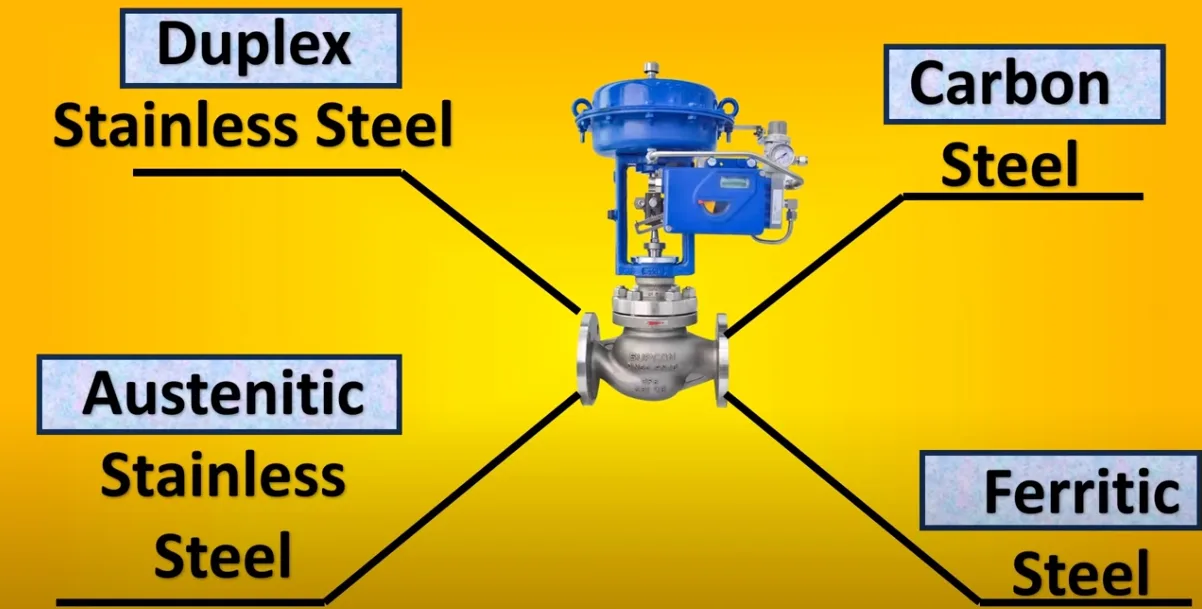

metal material :

Stainless steel: 304/316L stainless steel is suitable for dilute sulfuric acid, nitric acid and other oxidizing acids, but not resistant to hydrochloric acid, chloride ion. 316L is slightly more resistant to chloride pitting than 304.

Duplex steel: such as 2205,2507, with excellent resistance to chloride stress corrosion cracking, suitable for media containing chloride ions, such as salt water, hydrochloric acid (medium and low concentration).

Hastelloy C-276/C22: A top corrosion-resistant alloy that can withstand most strong acids (including hot concentrated hydrochloric acid), strong oxidizing media and wet chlorine gas, but is extremely expensive.

Titanium (Ti) and titanium alloys: excellent corrosion resistance to chloride ion, hypochlorite, wet chlorine gas, nitric acid, etc., but not resistant to fuming sulfuric acid, hydrofluoric acid.

Nickel (Ni) and nickel alloy: such as Monel (Monel) alloy, which has good corrosion resistance to hydrofluoric acid and fluorine medium.

Non-metallic/lining material:

Polytetrafluoroethylene (PTFE), known as the “King of Plastics”, exhibits exceptional resistance to nearly all strong acids, strong alkalis, and organic solvents (excluding molten alkali metals, fluorides, and chlorine trifluoride). With an exceptionally wide operating temperature range (-196℃ to 200℃), it is widely used as a lining or sealing material for ball valves and butterfly valves.

Perfluoroelastomer (FFKM), such as Kalrez® and Chemraz®, is the highest level of elastic sealing material with corrosion resistance comparable to PTFE and rubber elasticity for high performance O-rings and valve seats.

Polyvinylidene fluoride (PVDF): resistant to most acids, alkalis and halogens, with better mechanical strength than PTFE, but lower temperature limit (~ 90℃).

Enhanced polypropylene (RPP): good acid and alkali resistance, low cost, but poor temperature and pressure tolerance, often used in small diameter and mild working conditions.

Lining/plastic/gel: The valve body is lined with PTFE, PO, F46, etc., which takes into account the strength of the metal valve body and the corrosion resistance of non-metallic. It is a very cost-effective choice.

How to choose? You must consult the “corrosion data sheet” or consult the material supplier to determine the most appropriate material based on the specific medium, concentration and temperature. Do not guess by experience.

Select valve type

Different types of valves are suitable for different corrosive working conditions:

Advantages: fast switching, low flow resistance, good sealing (can achieve bidirectional zero leakage), compact structure.

Application: widely used for switching off corrosive media. Full diameter ball valve is especially suitable for cleaning pipeline or slurry media conditions.

Selection notes:

Lined Ball Valve (F46): The valve body is lined with F46 (FEP), the ball is covered with F46 or PFA, and the valve stem seal is made of PTFE or FFKM. This is one of the most commonly used and cost-effective choices for handling strong acids and alkalis, suitable for most medium-low temperature (≤150℃) corrosive conditions.

Metal hard sealing ball valve: using Hastelloy, titanium and other special metals, suitable for high temperature, high pressure or existing corrosion and wear harsh working conditions.

Advantages: simple structure, small size, light weight, low cost, quick opening and closing.

Application: large flow, low pressure difference, large diameter (DN>100) of corrosive medium cut off and regulation.

Selection notes:

Fluorinated lining butterfly valve (PTFE lined Butterfly Valve): The valve body is lined with PTFE, and the butterfly plate is covered with PTFE or special metal (such as 316L plated NiP). It is cheaper than fluorinated lining ball valve, and is an economical choice for large volume, large diameter corrosive gas/liquid pipeline.

Double-sided steel butterfly valve: suitable for corrosive and partial metal strength requirements.

Diaphragm Valve

Advantages: No packing box, absolute zero leakage. Smooth flow channel, not easy to block. The medium only contacts with the lining of the valve body and diaphragm.

Application: high risk, high toxicity, high purity medium (such as semiconductor, pharmaceutical industry), slurry, viscous fluid.

Selection notes: The diaphragm is the key component, and the material of the diaphragm should be selected according to the medium (such as PTFE lined rubber diaphragm, full PTFE diaphragm). The pressure and temperature resistance are relatively low.

Advantages: simple structure, quick switch, smooth flow path, good sealing.

Application: Suitable for corrosive media containing solid particles or slurry, such as electroplating solution, sewage.

Selection notes: fluorine lined (F46) or all plastic (such as PVDF) structure is often used.

Bellows Seal Globe Valve (BSEF)

Advantages: The metal bellows structure is adopted to completely eliminate the leakage point at the valve stem (zero external leakage), and the reliability is high.

Application: highly toxic, expensive, radioactive or highly volatile corrosive media (such as phosgene, hydrofluoric acid).

Selection notes: high cost, high flow resistance, usually only used in small diameter, must ensure absolute no leakage of critical situations.

Select sealing material

The material of the valve rod seal (packing) and the valve seat seal must be compatible with the medium.

PTFE: the most commonly used, excellent corrosion resistance, but cold flow and thermal expansion should be paid attention to.

Enhanced graphite: high temperature resistant, corrosion resistant, suitable for valve stem packing under high temperature conditions.

FFKM: Used for the highest requirements of elastic sealing, expensive.

PTFE composite filler: such as PTFE filler containing graphite and stainless steel wire, the performance is better.

Consider the operation

Manual: For infrequent operation and non-hazardous situations.

Pneumatic/electrical: For applications requiring frequent switching, remote control, or access to automation systems. For corrosive media, the selection of actuators should also consider environmental corrosion (e.g., selecting cylinders or motors with anti-corrosion coatings).

Quick reference table for selection of common media

medium | potency | Recommended valve type | Recommended valve body/inner part material | Important considerations |

| Sulfuric acid (H₂SO₄) | Tint (> 80%) | Metal hard sealing ball valve, stop valve | Carbon steel, 304/316 stainless steel | Note: concentrated sulfuric acid is oxidizing, can be used carbon steel; dilute sulfuric acid is strong corrosion, can not be used carbon steel! |

| Rare (<80%) | Fluorine lined ball valve, fluorine lined butterfly valve | Sheathed PTFE/F46 | The flow rate should not be too high to prevent the lining from peeling | |

| hydrochloric acid (HCl) | All concentrations | Fluorine-lined ball valve, diaphragm valve, PVDF ball valve | Consequently PTFE/F46, PVDF, Hastelloy | The use of any stainless steel (including 316L) is strictly prohibited. When the temperature and pressure are not high, fluorine-lined valves are preferred. |

| Nitric acid (HNO₃) | All concentrations | Stainless steel ball valve, stop valve | 304,316L stainless steel | 304/316L is very resistant to nitric acid corrosion at room temperature. Pyrophosphoric acid requires aluminum or titanium. |

| hydrofluoric acid (HF) | All concentrations | Monel alloy valve, fluorine lined valve | Monel alloy, lined with PTFE | Extremely dangerous, corrosive to glass and silicon containing materials. Valve inspection is extremely strict. |

| Sodium hydroxide (NaOH) | Rich, hot | Stainless steel ball valve, stop valve | 304,316L stainless steel | Room temperature dilute alkali solution can be used, but hot concentrated alkali solution will cause stress corrosion cracking of stainless steel, so attention should be paid to temperature. |

| ( liquid caustic ) | All concentrations | Fluorinated lining ball valve, PVDF ball valve | Sheathed PTFE/F46, PVDF | PTFE and PVDF are safe choices for all concentrations of alkali. |

| Wet chlorine gas (Cl₂) | – | Fluorine-lined valve, titanium valve | Backed PTFE, titanium | Wet chlorine gas is extremely corrosive, dry chlorine gas can be used for carbon steel. |